Recommend

Remove File

Remove document <span id="remove-document-name"></span> from <span id="remove-cart-name"></span>?

The development of offshore wind turbines is driving the demand for larger turbines which are more cost-effective. Indeed there are now 6,000kW machines on the market and 10,000kW machines under development. This growth in the size of machines has lead to demands for more high-quality and reliable components specially designed for the wind turbine market.

“Conductix-Wampfler is a world leader in the supply of energy and data transmission solutions, and has responded as this growing market has demanded more from Conductix-Wampfler products” says Roger Millington, Global Market Manager for Renewable & Offshore Energy, Automation Division, “The group Centers of Excellence have risen to the challenge to take our existing products and develop customized high-quality solutions for the wind turbine applications. We are uniquely well-placed as an international company with product development centers in Europe and USA, sales outlets in all major countries and production operations across Europe, the Americas and Asia to serve this global market now and in the future”.

There are two key applications within a wind turbine for which Conductix-Wampfler provides solutions:

TowerbussTM

Traditionally, wind turbine manufacturers have used cables to transfer power from the top of the tower to ground-level. Whilst this may be manageable for smaller towers with few cables, the trend towards 100m+ high towers has meant that the handling and fixing of multiple cables becomes a major task. Conductix-Wampfler have developed a unique alternative solution, known as TowerbussTM, based on our extensive conductor bar expertise. TowerbussTM provides both material cost and installation labor savings of 20 to 30% over cable solutions. This UL approved product utilizes a highly corrosion-resistant, hardened aluminum conductor especially designed for electrical applications. The conductor is completely shrouded in a protective insulating cover, supported at the base and guided along their length by brackets fixed to the tower wall. The system is positioned to clear the tower section flanges thereby allowing use of bolted mechanical joints to create a continuous column of bussbar, and eliminating the need for expensive multiple cable connections, as can be seen from the above photograph. As well as being flexible enough to cater for tower movements, a key advantage of TowerbussTM is its modular design. The number and size of TowerbussTM poles can be customized to each customer’s requirements. Important labor cost-savings can be realized by pre-installing TowerbussTM sections into the tower sections at the tower manufacturer’s site. Minimal field labor is then required to connect the conductors at the tower sections joints after the tower has been erected. TowerbussTM was initially developed in conjunction with a major US wind turbine manufacturer and has since been used uniquely in all their 2.5 MW machines. It is now being customized by Conductix-Wampfler for new larger turbines, especially offshore machines under development by international turbine manufacturers, and the adoption of the TowerbussTM solution is expected to grow significantly in the coming years.

Traditionally, wind turbine manufacturers have used cables to transfer power from the top of the tower to ground-level. Whilst this may be manageable for smaller towers with few cables, the trend towards 100m+ high towers has meant that the handling and fixing of multiple cables becomes a major task. Conductix-Wampfler have developed a unique alternative solution, known as TowerbussTM, based on our extensive conductor bar expertise. TowerbussTM provides both material cost and installation labor savings of 20 to 30% over cable solutions. This UL approved product utilizes a highly corrosion-resistant, hardened aluminum conductor especially designed for electrical applications. The conductor is completely shrouded in a protective insulating cover, supported at the base and guided along their length by brackets fixed to the tower wall. The system is positioned to clear the tower section flanges thereby allowing use of bolted mechanical joints to create a continuous column of bussbar, and eliminating the need for expensive multiple cable connections, as can be seen from the above photograph. As well as being flexible enough to cater for tower movements, a key advantage of TowerbussTM is its modular design. The number and size of TowerbussTM poles can be customized to each customer’s requirements. Important labor cost-savings can be realized by pre-installing TowerbussTM sections into the tower sections at the tower manufacturer’s site. Minimal field labor is then required to connect the conductors at the tower sections joints after the tower has been erected. TowerbussTM was initially developed in conjunction with a major US wind turbine manufacturer and has since been used uniquely in all their 2.5 MW machines. It is now being customized by Conductix-Wampfler for new larger turbines, especially offshore machines under development by international turbine manufacturers, and the adoption of the TowerbussTM solution is expected to grow significantly in the coming years.

Pitch Control Sliprings (PCS)

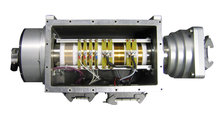

One of the keys to successful operation of a wind turbine is in the control of the complex rotor pitch control and safety systems which require various power and data to be transferred with high integrity to the rotating hub in varying wind conditions. To meet the performance requirements of these safety-critical systems in harsh environments, Conductix-Wampfler has developed a new PCS slipring type utilizing their considerable experience and expertise of sliprings in the automation industry. The conditions under which the sliprings must work are not dissimilar for all large turbines, so there is a high-level core specification to meet these conditions. However because all manufacturers have different (and confidential) control requirements, the slipring is modular in design to enable the individual turbine manufacturer specifications to be met with a customized slipring solution. A typical layout is shown in the photograph above. The key to providing the requisite levels of power circuits combined with the requirement for high-integrity data transmission is the technology of gold-plated collector rings and a unique gold-alloy wire brush arrangement developed by Conductix-Wampfler. This guarantees that the transmission requirements are met over long periods with only minimal maintenance requirements, typically 100 million revolutions, which is a key factor in cost-effective wind turbine operation. The slipring can also be specified with fiber-optic rotary joint (FORJ) for optical data transmission, anti-condensation heaters, positional encoders and with mechanical housing and fittings to meet all manufacturers interface requirements. Conductix-Wampfler also offer a service exchange scheme which helps to minimize costly service engineer time on site.

One of the keys to successful operation of a wind turbine is in the control of the complex rotor pitch control and safety systems which require various power and data to be transferred with high integrity to the rotating hub in varying wind conditions. To meet the performance requirements of these safety-critical systems in harsh environments, Conductix-Wampfler has developed a new PCS slipring type utilizing their considerable experience and expertise of sliprings in the automation industry. The conditions under which the sliprings must work are not dissimilar for all large turbines, so there is a high-level core specification to meet these conditions. However because all manufacturers have different (and confidential) control requirements, the slipring is modular in design to enable the individual turbine manufacturer specifications to be met with a customized slipring solution. A typical layout is shown in the photograph above. The key to providing the requisite levels of power circuits combined with the requirement for high-integrity data transmission is the technology of gold-plated collector rings and a unique gold-alloy wire brush arrangement developed by Conductix-Wampfler. This guarantees that the transmission requirements are met over long periods with only minimal maintenance requirements, typically 100 million revolutions, which is a key factor in cost-effective wind turbine operation. The slipring can also be specified with fiber-optic rotary joint (FORJ) for optical data transmission, anti-condensation heaters, positional encoders and with mechanical housing and fittings to meet all manufacturers interface requirements. Conductix-Wampfler also offer a service exchange scheme which helps to minimize costly service engineer time on site.

In addition to these Conductix-Wampfler products for direct incorporation into the wind turbines, Conductix-Wampfler products are also contributing to the development of wind energy market in other ways. Because of the growing demand for wind turbines, almost all manufacturers have needed to expand their production and many have created, or plan to establish, new manufacturing plants. Because of the nature and size of the products, wind turbine manufacturing plants have significant materials handling tasks and require modern cranes, hoists and material handling equipment. Conductix-Wampfler is a global leader in power and data transmission systems for materials handling and has provided solutions to all the major material handling, crane and hoist manufacturers for many years. Behind the scenes, and around the world, Conductix-Wampfler is quietly and efficiently powering the production of many of the modern wind turbines.

Short Profile of Conductix-Wampfler

Conductix-Wampfler is the world’s leading supplier of mobile energy supply and data transmission systems.

With own companies and several partners Conductix-Wampfler is present in nearly all relevant countries. With about 1000 employees across the globe, the group generated sales of about € 163 million in fiscal 2009.