Cranes

Lifting and moving of goods is part of almost every production, assembly, or logistic process. Depending on the size and weight of goods and materials, machines for lifting can be designed very differently. However, they all have vertical and horizontal movements in common. Next to floor mounted transportation and lifting equipment, cranes are the most used material handling equipment for this task. From simple hoists on fixed or swiveling beams, to overhead cranes, to fully automated and dedicated process cranes, the range of crane types is as wide as the kinds of goods that are handled by them – all over the world, every day. Energy and data transmission systems play a crucial role in the safe, reliable, and efficient operation of all types of cranes. Due to the different designs and functionalities of cranes, power supply and data transmission systems need to be very dedicated to fit the exact requirements. Also, the wide range of different environments where cranes operate, such as factories, steel mills, aluminum smelters, scrape cranes, timber mills, and waste-to-energy (WCR) puts very high and specialized demands on energy and data transmission systems.

Conductix-Wampfler is the worldwide leader in electrifying cranes. We offer standardized solutions for all types of cranes and can handle customized needs as well. Conductix-Wampfler offers a large network of Sales and Engineering facilities close to our customers. Local stocks and short lead times on standardized items guarantee the highest possible level of support for our customers.

Conductor Rails – for the runway travel of factory cranes, single pole insulated, multi pole or enclosed conductor rail systems have proven to be the most reliable and cost-effective solution. Cross travel on cranes can be handled with conductor bars as well, using dedicated data transfer systems

Cable Festoon Systems – cross travel on cranes can be equipped with traditional but extremely reliable and durable festoon systems (motor-driven or none motor-driven)

Energy Guiding Chain – can also manage cables for the cross travel on cranes as well as for cranes with extendable booms.

Spring-Driven or Motor-Driven Cable Reels – can manage cables used in vertical lift applications.

Slip Rings – pass power and control to the moving part of cranes that rotate 360 degrees.

Rubber or Cellular Bumpers – cushion the direct part-to-part impacts of crane elements.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of crane applications.

Brückenkran in einem Rohrwalzwerk

Applikation

Brückenkran in einem Rohrwalzwerk

Land

Russland

Stadt

Chelyabinsk

Vertretung

Conductix-Wampfler OOO [RUS]

Betreiber

CHELPIPE – Vysota 239

Technische Anforderung[en]

Hauptstromzuführung für einen Brückenkran

Systemverlauf

Linear

Verfahrweg [Verbraucher]

- 4 Systeme, à 720 m, Gesamtlänge: 2880 m [Programm 0812, SinglePowerLine]

- 35 m [Program 7100, Motorkabeltrommel]

Produkt[e]

- Schleifleitung, Programm 0812, SinglePowerLine

- Motorkabeltrommel, Programm 7100 [Verschiebewagen]

Anzahl Pole

3+PE

Strom

400 A

Spannung

380 V

Relevant Products

Single PowerLine 0812

Additional information

Einzelpolige Schleifleitung für den vorzugsweise geraden Bahnverlauf.

Wichtige Merkmale

- Hohe Verfügbarkeit auch bei raueren Umgebungsbedingungen durch robusten Aufbau und unterschiedlicher Leitungswerkstoffe

- Sicherheit durch Fingerschutz und hochwertige Isolation

- Einfache und exakte Montage mit kombinierbaren mehrpoligen Schienenhaltern (3, 4 und 5 Pole)

- Unbegrenzte Polzahl auch für komplexe Anwendungen

- Kurvengängigkeit durch Bogensegmente

Typische Applikationen

- Krananlagen im mittleren Leistungsbereich

- People Mover / Personentransport-Systeme

- Sonderanlagen

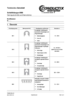

Product data

Standard Einsatzdaten

- Nennstrombereiche (100% ED) [A]: 25 | 200 | 250 | 320 | 400

- Nennspannung [V]: 690

- Schienenlänge [mm]: 4.000

- Außenabmessungen (Pol) [mm]: 18,0 x 26,0

- Einsatzbereich: Innen und geschützter Außenbereich

- Bahnverlauf: gerade / Kurvensegmente möglich

Downloads

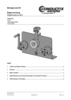

Motortrommeln - Kompakt Serie [C]

Additional information

Optimaler Korrosionsschutz auch unter aggressiven Umgebungsbedingungen. Seitenschilde und Trommelkörper aus feuerverzinktem Stahlblech.

Gesicherter Betrieb mit standardisierten Schleifringkörpern.

Hohe Lebensdauer durch verschleißfreie und berührungslose Momentenübertragung - Normmotor mit Magnetkupplung.

Hauptanwendungen:

- Portalkrane

- Hallenkrane

- Greifer- und Magnetanlagen

- Verschiebewagen

- Längsräumer in Kläranlagen

- Licht- und Bühnentechnik

Product data

Standard Einsatzdaten

Fahrgeschwindigkeit: bis zu 100 m/min

Wickellänge: max. 200 m

Außendurchmesser Trommelkörper:

- breit wickelnd: 400 mm - 1.700 mm

- spiralig oder 3-2-3 wickelnd: 1.100 mm - 3.600 mm

Getriebe:

- Typ W: 100 Nm - 400 Nm

- Typ BNA: 300 Nm - 700 Nm

Schleifringkörper:

- Spannung/Strom max: 690 V – 200 A

- Signale & Daten max: 500V / 690 V - mA – 25 A

Temperaturbereich: -20 °C - +60 °C

Downloads

Conductix-Wampfler GmbH

Weil am Rhein

Rheinstrasse 27 + 33

79576 Weil am Rhein

Germany

Phone: +49 (0) 7621 662 0

Fax: +49 (0) 7621 662 144

www.conductix.de

info.de@conductix.com

Supplier Self Disclosure General Terms and Conditions of Delivery, Payment and Installation General Terms and Conditions of Purchasing Conductix-Wampfler GmbH Environmental Statement 2020 Conductix-Wampfler GmbH

Conductix-Wampfler Automation GmbH

Potsdam

Handelshof 16 A

14478 Potsdam

Germany

Phone: +49 (0) 331 887344 - 0

www.conductix.de

info.potsdam@conductix.com

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Facebook. With the activation data will be transmitted to third parties.mit Facebook verbunden

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Twitter. With the activation data will be transmitted to third parties.nicht mit Twitter verbunden

![Motor Driven Reels - Motor Driven Reels Compact [C] Series Motor Driven Reels Compact [C] Series](https://www.conductix.de/sites/default/files/styles/teaser-image/public/compact_motor_driven_reels_neu.jpg?itok=hC9n1c0E)