Cranes

Lifting and moving of goods is part of almost every production, assembly, or logistic process. Depending on the size and weight of goods and materials, machines for lifting can be designed very differently. However, they all have vertical and horizontal movements in common. Next to floor mounted transportation and lifting equipment, cranes are the most used material handling equipment for this task. From simple hoists on fixed or swiveling beams, to overhead cranes, to fully automated and dedicated process cranes, the range of crane types is as wide as the kinds of goods that are handled by them – all over the world, every day. Energy and data transmission systems play a crucial role in the safe, reliable, and efficient operation of all types of cranes. Due to the different designs and functionalities of cranes, power supply and data transmission systems need to be very dedicated to fit the exact requirements. Also, the wide range of different environments where cranes operate, such as factories, steel mills, aluminum smelters, scrape cranes, timber mills, and waste-to-energy (WCR) puts very high and specialized demands on energy and data transmission systems.

Conductix-Wampfler is the worldwide leader in electrifying cranes. We offer standardized solutions for all types of cranes and can handle customized needs as well. Conductix-Wampfler offers a large network of Sales and Engineering facilities close to our customers. Local stocks and short lead times on standardized items guarantee the highest possible level of support for our customers.

Conductor Rails – for the runway travel of factory cranes, single pole insulated, multi pole or enclosed conductor rail systems have proven to be the most reliable and cost-effective solution. Cross travel on cranes can be handled with conductor bars as well, using dedicated data transfer systems

Cable Festoon Systems – cross travel on cranes can be equipped with traditional but extremely reliable and durable festoon systems (motor-driven or none motor-driven)

Energy Guiding Chain – can also manage cables for the cross travel on cranes as well as for cranes with extendable booms.

Spring-Driven or Motor-Driven Cable Reels – can manage cables used in vertical lift applications.

Slip Rings – pass power and control to the moving part of cranes that rotate 360 degrees.

Rubber or Cellular Bumpers – cushion the direct part-to-part impacts of crane elements.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of crane applications.

-

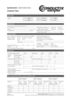

Short Overhead Bridge Crane in production of prefabricated house manufacture

Reference Report

[REF0831-0013-E]

Short Overhead Bridge Crane in production of prefabricated house manufacture

Application

Short Overhead Bridge Crane in production of prefabricated house manufacture

Country

Germany

City

Alderbach-Uttigkofen

Representative office

Conductix-Wampfler GmbH [D]

Customer

Haslinger GmbH Metallbau + Krantechnik

Technical requirement[s]

Energy supply to the crab

Travel distance [Load]

12 m

Travel speed [Load]

32 m/min

Product[s]

Conductor Rail, Program 0831 MultiLine

Quantity of poles

5

Current

60 A

Voltage

400 V

Additional information

- Due to the limited installation space of the crane was designed as a radio crane

- For energy transfer therefore the compact conductor rails was processing 0831 integrated in the carrier profile

- Data transmission to the crab via radio

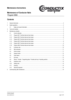

Relevant Products

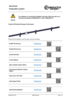

MultiLine 0831

Additional information

Multipole compact conductor rail for straight tracks in indoor applications.

Special features

- Fast and economical mounting through multipole design, clamp hangers and plug-in connector technology

- Free combination of 3-, 4- and 5-pole units

- High safety level and optimized mechanical characteristics through joint insulation profile

- Compact design with optimum distance between the poles

- Easy maintenance – rail segments can be easily cleaned and replaced

Main applications

- High Storage Systems (AS/RS)

- Process and production cranes

- Customized solutions and special purpose equipment

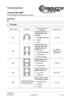

Product data

Standard application data

- Nominal Current (at 100% duty cycle) [A]: 10 | 32 | 60 | 100 | 125

- Voltage Grade [V]: 690 (Hand safe array 500 V)

- Rail Length [mm]: 4.000 [16.40 ft]

- External Dimensions [mm]: 3-pole: 26,0 x 62 [1.02" x 2.44"]; 4-pole: 26,0 x 80,0 [1.02" x 3.15"]; 5-pole: 26,0 x 98,0 [1.02" x 3.86"]

- Operating Conditions: for indoor and weather-protected outdoor applications

- Track Configuration: straight tracks

Downloads

Conductix-Wampfler GmbH

Weil am Rhein

Rheinstrasse 27 + 33

79576 Weil am Rhein

Germany

Phone: +49 (0) 7621 662 0

Fax: +49 (0) 7621 662 144

www.conductix.de

info.de@conductix.com

Supplier Self Disclosure General Terms and Conditions of Delivery, Payment and Installation General Terms and Conditions of Purchasing Conductix-Wampfler GmbH Environmental Statement 2020 Conductix-Wampfler GmbH

Conductix-Wampfler Automation GmbH

Potsdam

Handelshof 16 A

14478 Potsdam

Germany

Phone: +49 (0) 331 887344 - 0

www.conductix.de

info.potsdam@conductix.com